Time Travel Through the History of Manufacturing

January 26, 2014

3D printing is our thing, but as makers, we have an insatiable love for textiles as well. Whenever I look closely at the layers of polymer that make up a 3D print, I am reminded of how it is built up of repeating threads just like a textile. Both processes are forms of additive manufacturing with one looking back and another looking forward in the history of manufacturing. As 3D printing becomes more and more mature as a technology, it seems as though the tradition has come full circle.

In our latest collaboration, Hybridized Cloth, with textile artist Ozana Gherman, the goal was to see what would happen if we dove into the history of manufacturing to pluck out some of the most traditional textile making techniques to concoct a mashup with the highly digital fabrication method of 3D printing. So, we set out to experiment with various forms and techniques native to each manufacturing method, attempting to marry the soft intricacy of traditional weaving with the computerized beauty of digital fabrication.

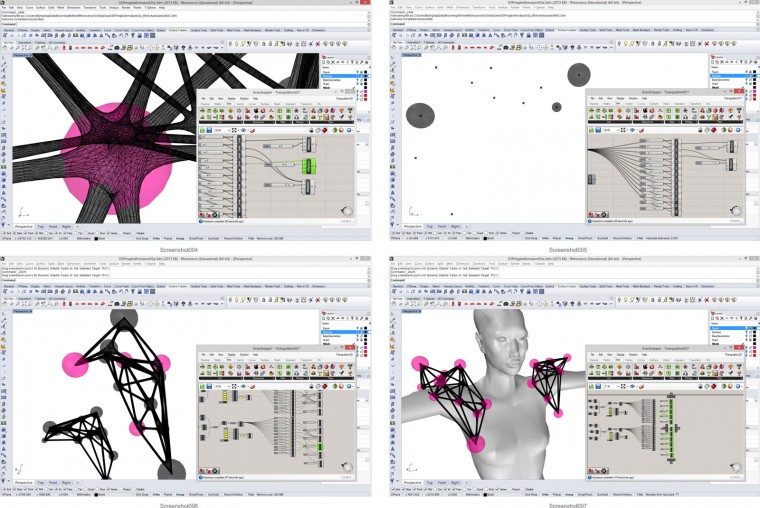

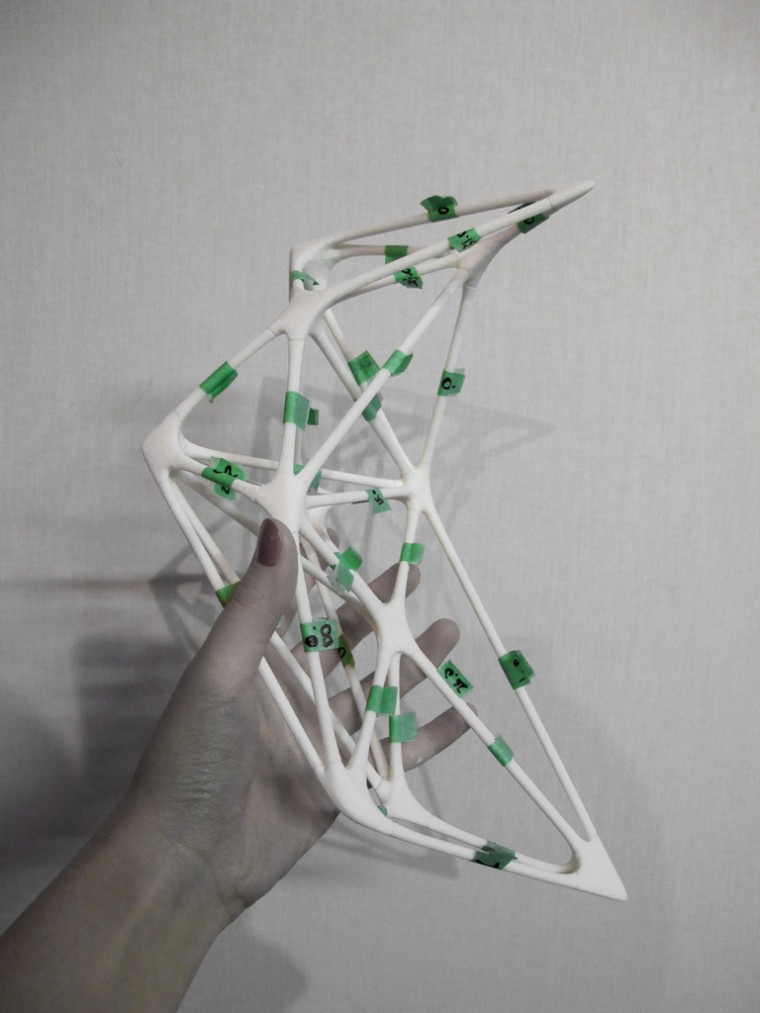

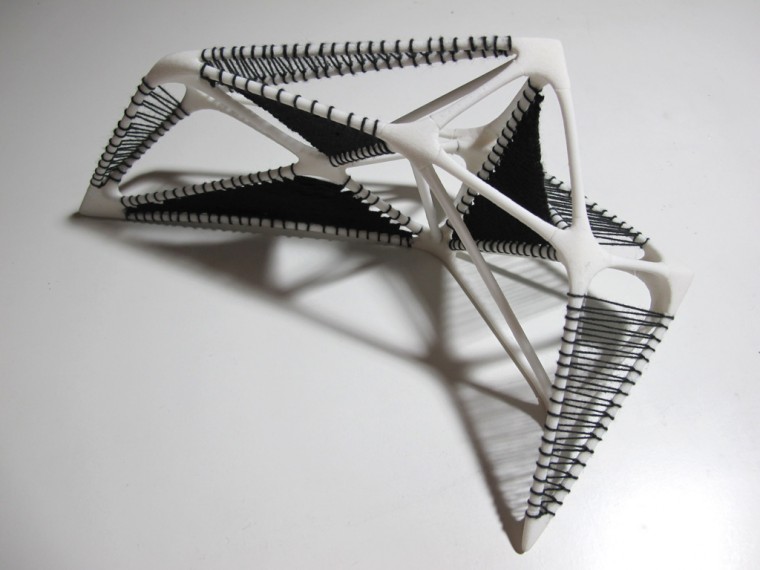

Our process began in digital realm where we usually start a 3D printing project. But unique to the multi-medium approach of integrating textiles, we decided to create something that would be intimate to the human form. To do this, we tested and refined a series of shapes that would respond to a 3D body scan. By going back and forth between 3D models and physical prototypes, we developed a pair of triangulating structures that nestled comfortably on the shoulder.

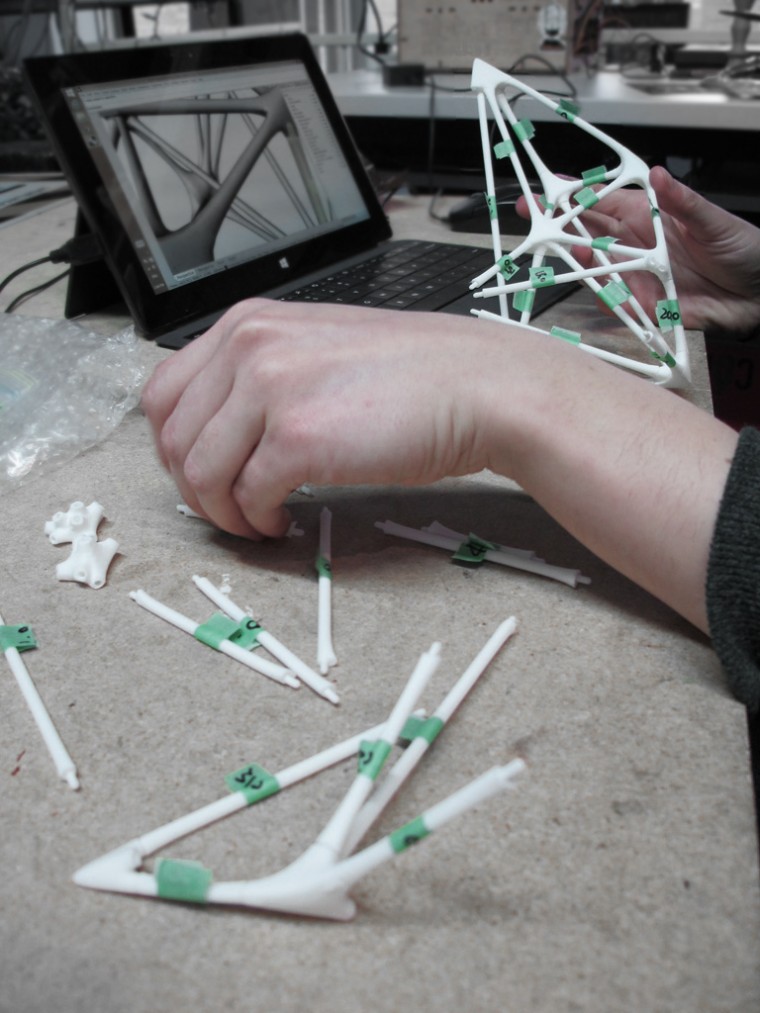

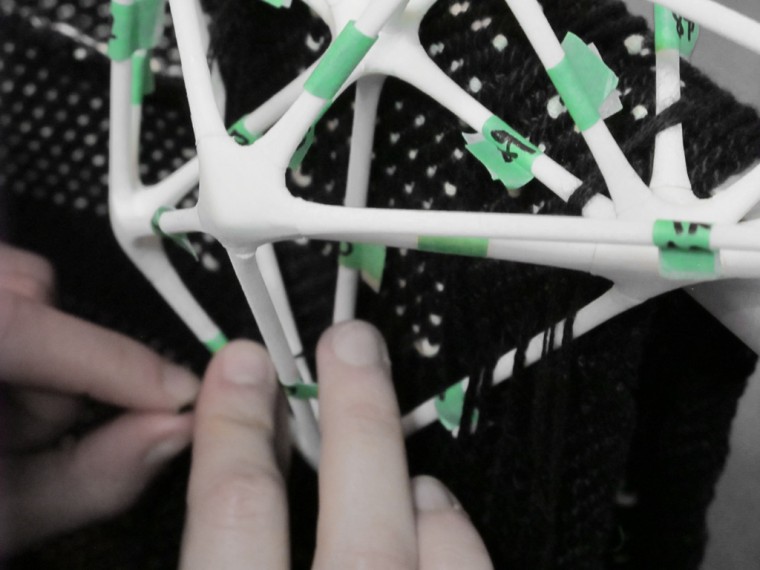

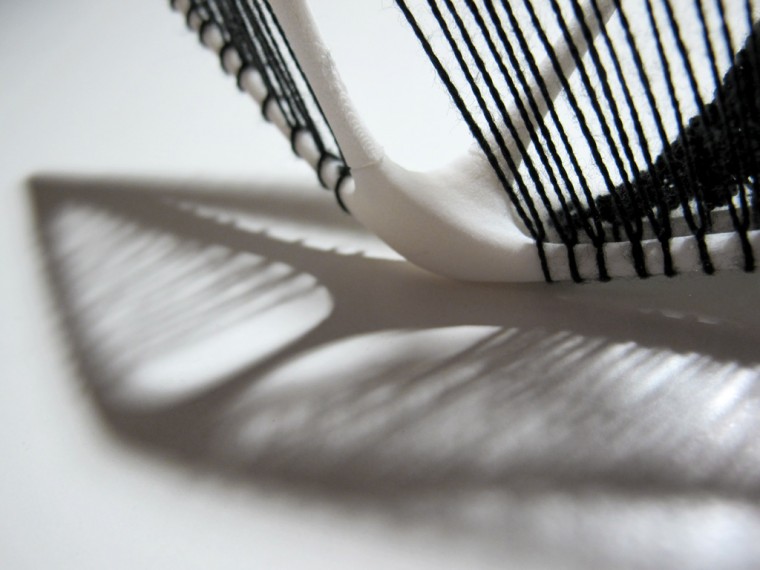

These structures were generated with specialized software and materialized with a 3D printer. They were produced as a kit of parts consisting of nodes and connectors, each indexed for easy assembly. Each connecting member was marked with regularly spaced notches in the digital file in anticipation of the weaving process that would follow. The entire piece came together via pin and hole connections, transforming our digital drawings into articulated three-dimensional forms.

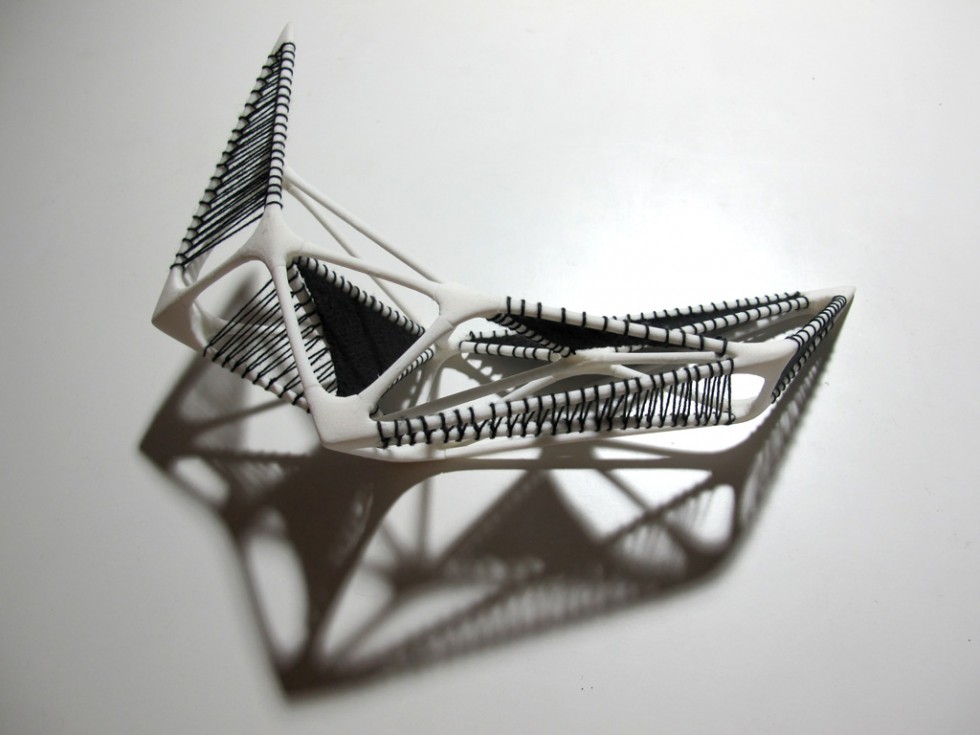

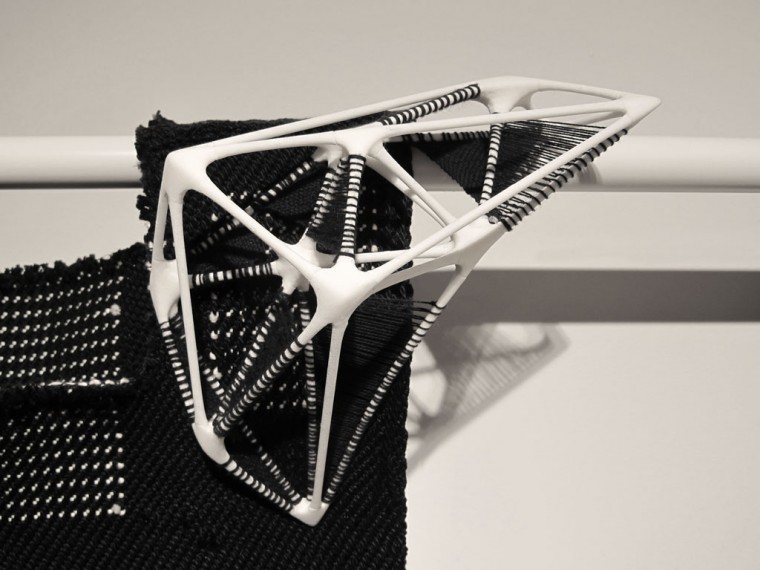

At this point, the digital manufacturing process was complete. We then transitioned to a completely hand-crafted process where the finished triangulating structures became the frame on which we wrapped a thick black warp for weaving. The notches that were designed into the members made it very easy to guide each thread of yarn around the structure. We started the weave by filling in the internal cells of the armature with panels of varying porosity, then moved outwards and began working on an entire garment.

We explored several indigenous weaving techniques and a myriad of embroidery stitches to create our contemporary version of the huipil, a traditional Guatemalan garb. We chose the huipil for its simplicity and historical roots to contrast the modern fabrication methods used in the piece. We also employed the associated hand-crafting techniques in the creation of the textile. This included back-strap weaving, the colloquial use of a portable back-strap loom, which was secured around the weaver’s waist and attached to a structural element such as a tree or post to create necessary tension. Ozana did this by securing the weave on her studio door!

From start to finish, the making of this piece involved going back and forth in the history of manufacturing. Interestingly enough, the traditional techniques were augmented by the digital ones through computerized manufacturing. By working digitally, we were able to create a three-dimensional framework on which to weave rather than creating a series of 2D patterns to stitch together. The result is a hybrid way of producing 3D textiles that draws from traditional manufacturing while integrating it with budding digital processes. This piece is a part of a larger study on the ritual of making, more developments will follow as we continue to experiment and play with our favorite tools and materials.

Hybridized Cloth will be on display until March 15, 2014 at Craft Ontario as a part of the Hand and Machine show and Toronto Design Offsite Festival. We are running a special 3D Printing meets Craft workshop in the Craft Ontario gallery on March 9th where attendees will be designing and making 3D printed beads for a DIY leather wristlet. Sign up now before tickets are gone!

Check out all the beautiful pieces in the Hand & Machine show in this highlight reel.

RELATED POSTS | Eamespunk – Remixing a Classic