Each 3D printing project is unique in it’s own way. Sometimes you want something to be strong, or finely detailed, or with many interconnected parts. For almost every design need there’s a unique material consideration. Here’s a quick introduction to all the interesting materials you can 3D print with at Hot Pop.

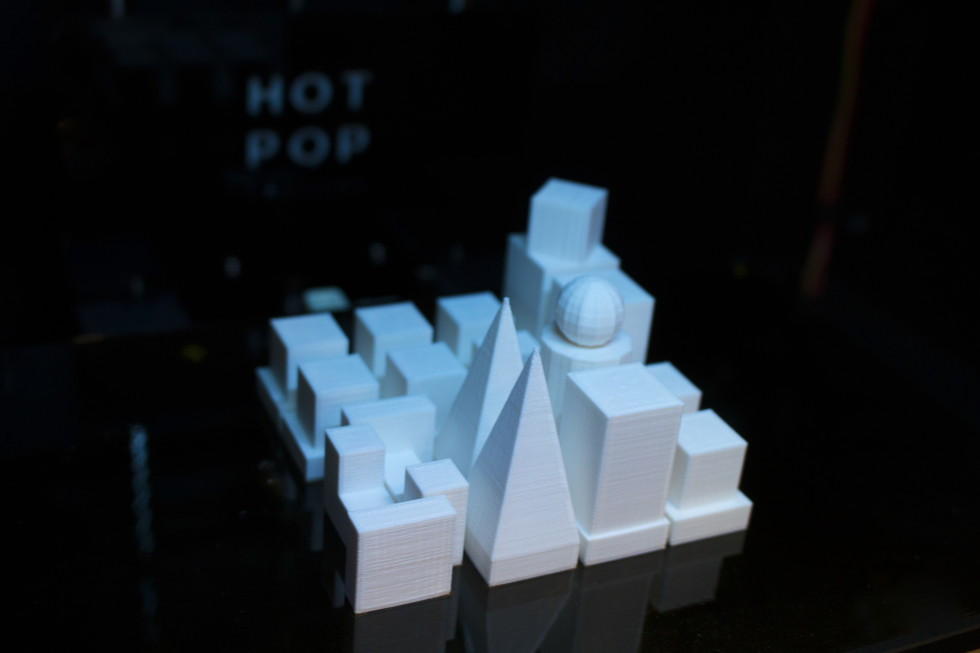

ABS & PLA Plastic

Resolution 3/5 Durability 4/5 Cost 3/5

ABS is a really strong thermoplastic. If you think an object might be dropped or handled (such as a phone case or chess piece) then ABS is the best option. PLA is also a thermoplastic and is very similar to ABS in terms of its physical properties. The main difference is that PLA is a biodegradable plastic that comes from natural resources such as corn starch. The materials are typically printed on a FDM 3D printer which is very good at producing simple geometries at low to medium resolution, perfect for preliminary prototypes to test out an idea. For more plastic material options visit https://shop.plasticmaterials.net/category/abrtools.

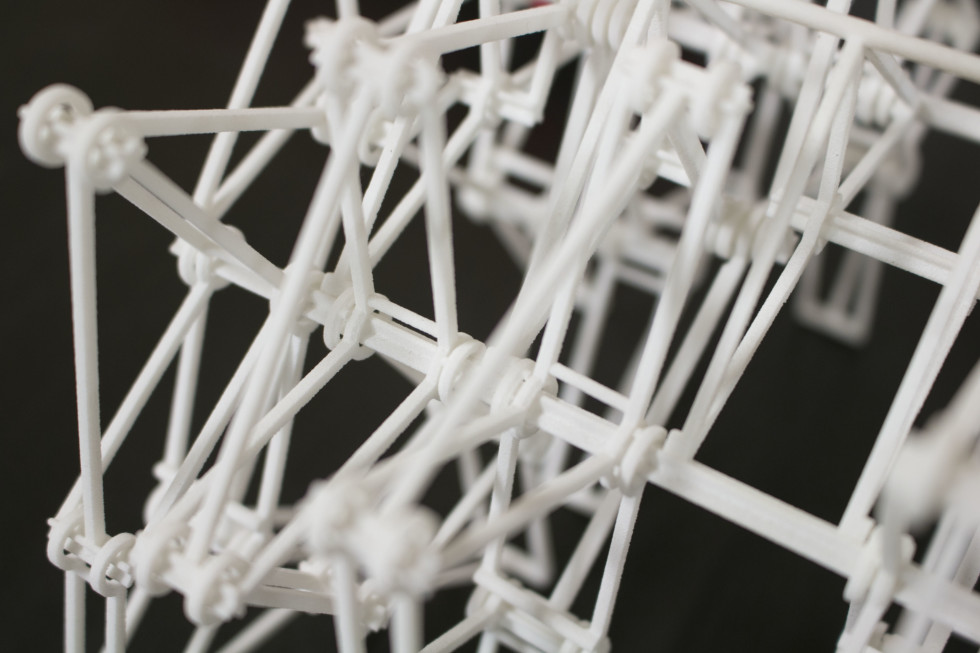

Nylon

Resolution 5/5 Durability 5/5 Cost 4/5

If you’re working on a project with lots of interconnected moving parts use nylon. With nylon you can make functioning hinges and gears right out of the printer. It’s strong while also providing some flexibility if you print thin parts. Details can be as small as 0.7mm, and it’s available in standard colours.

Alumide

Resolution 5/5 Durability 5/5 Cost 4/5

Alumide is a mix of fine aluminum particles and polyamide power. This strong material is the perfect solution if you want something printed in metallic colours or with moving parts. Similar to sandstone it has a brittle surface that is somewhat porous, and can be used for fine details (minimum 0.7mm).

Full Colour Sandstone

Resolution 4/5 Durability 2/5 Cost 5/5

Sandstone is the only 3D printing process that allows you to make full colour prints so it’s perfect for figurines or small sculptures with lots of colour. You can get a lot of fine details with sandstone (minimum 0.7mm thickness) and it’s quite strong with a slightly brittle texture.

Wax

Resolution 5/5 Durability 1/5 Cost 5/5

For Jewelry and finely detailed parts, 3D printed wax is an excellent way of making moulds. It let’s you work on really finely detailed parts on the computer so you can cast structures and engravings that would be otherwise impossible to achieve with manual methods. Similar to other forms of 3D printing, the wax is melted in the printer and then solidifies once printed. If you’re accustomed with lost-wax casting, 3D printing can help save you a step in the process.

If you have any questions about a 3D printing project you have in mind, get in touch!

Don’t forget to check out useful information about how to get your project made by visiting our 3D printing MATERIALS, PRICING GUIDE, TURNAROUND, and DESIGN GUIDE pages.

Images of rings via Elizabete Ludviks