3D Printing Price Guide

The easiest way to get pricing for your project is to submit your 3D model file for a quote.

Because of the custom nature of 3D printing applications, our services are quoted on a project by project basis. In general, the total cost of a project is a combination of 3D file preparation or repair if needed and machine time based on volume and geometry.

Below is a breakdown of factors we consider when quoting your project.

3D File Preparation and Repair

Exporting your 3D models as 1:1 scale, unioned and manifold meshes is the easiest and cheapest way to get a project printed. Typically, with a 3D mesh (in STL or OBJ file format) that meets these requirements, we are able to produce your design with no setup or file prep costs at all. See our Design Guide for how to prepare your 3D files.

In case your project assets do not meet the requirements for production, we can provide our services to help you move your project forward. Your price will vary depending on the amount of time required to generate a production ready file. Budgetary estimates are provided at the beginning of a project on an hourly basis, actual time will be billed.

Materials

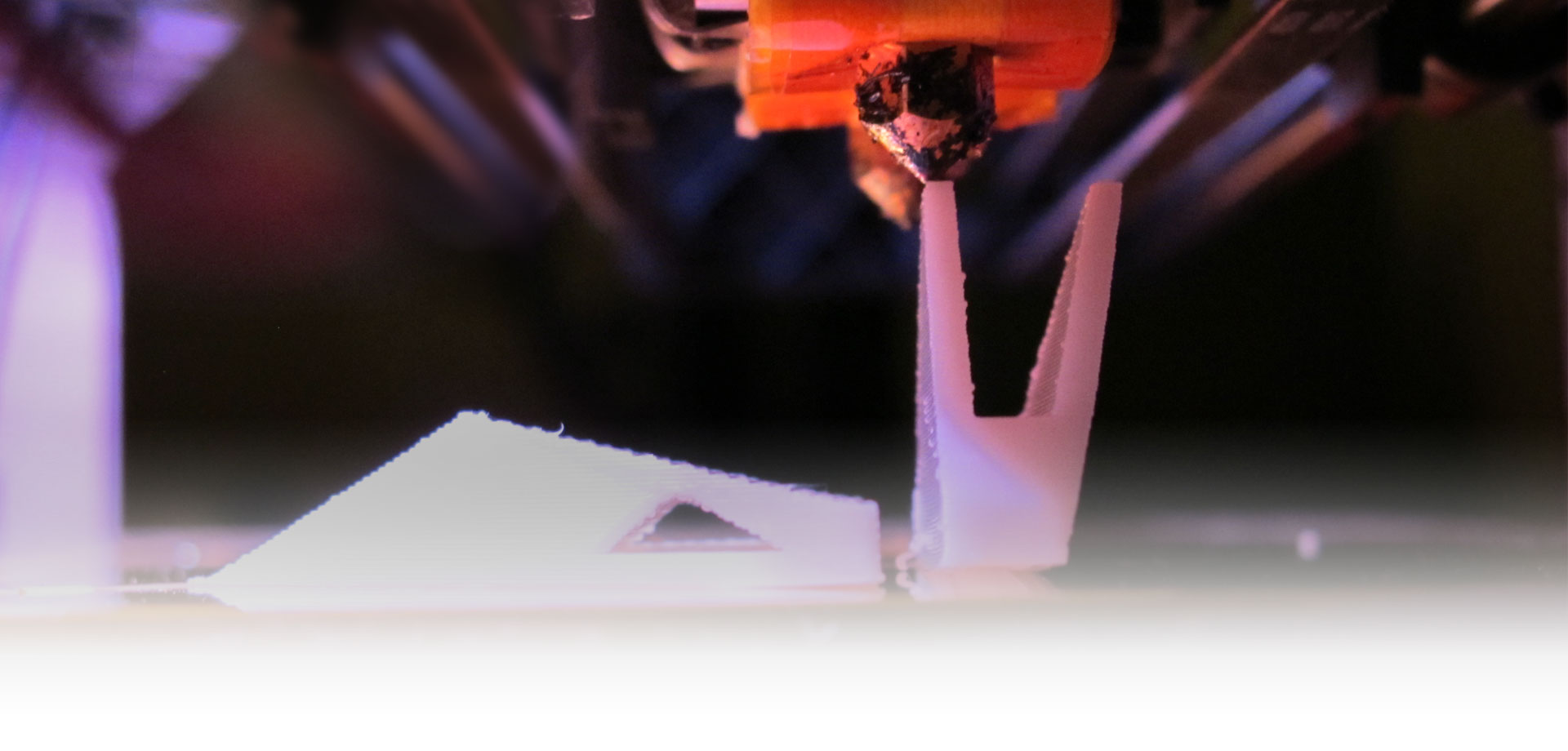

Production costs vary depending on the material and process chosen. In general, FDM prints in ABS and PLA are more affordable than SLS prints in nylon, sandstone, and alumide. However, many other factors including volume, geometry, and infill density will affect the cost as well. We can usually make a recommendation upon reviewing your 3D model file. For more information on the differences between our various 3D printing materials, refer to our SLS vs FDM post.

Size

The biggest cost driver of all our 3D printing processes is the size of your model, this factor greatly impacts the overall volume and machine time, which dictates the production cost. Because the volume of an object increases much faster than the linear dimensions do, even a small incremental change in size will have an exponential impact on the production cost. See our Design Guide for size limitations and requirements.

Infill Density

Related to the impact of a model’s overall size when considering your project budget, the internal density of a design will also impact machine time, and therefore, the production cost. Typically, we recommend our clients create hollow or porous designs where possible to minimize overall volume. This is especially important when the size of the model is required to be quite large. It helps to greatly reduce the amount of time required to produce the model and as a consequence the overall cost. See our Design Guide for minimum wall thicknesses and escape hole requirements.

Turnaround

Our standard turn around time is typically 1 week. Rush service is available if you're in a hurry and but it will be more expensive as it requires us to change our production schedule to fit your project in ahead of other customers.

Start your project now: